| Project Owner... |

DBFZ Deutsches Biomasseforschungszentrum

|

| Project name |

Pilot-SBG

|

| Status |

operational

|

| Startup |

2018

|

| Country |

Germany

|

| Street |

Torgauer Straße 116

|

| City |

Leipzig

|

| ZIP |

04347

|

| Type |

TRL 6-7 Demonstration

|

| Technology |

Other Technology

|

| Technology additional information |

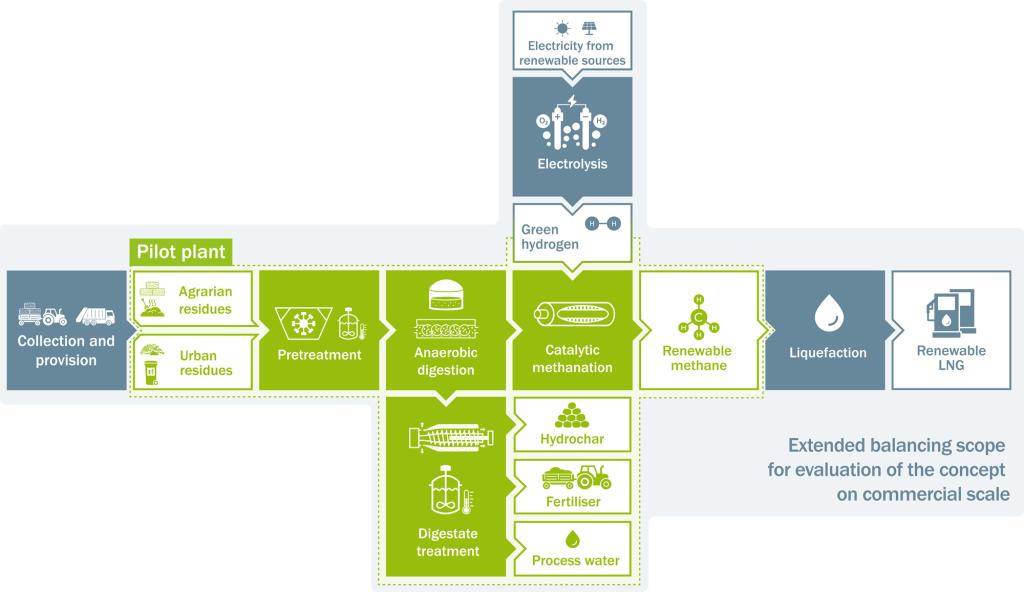

Combination of methanation, anaerobic digestion (AD), hydrothermal processes (HTP), and several separation units

|

| Raw Material |

organic residues and waste streams

|

| Input 1 |

Straw, Manure, Green Cuttings, organic fraction of municipal waste (8 t/y

)

|

| Output 1 |

biogas (1 t/y

)

|

| Output additional information |

Methane, 0.59-0.67 t/a, Fertilizer, 5-7 t/a, Hydrochar, 2 t/a; Rough approximation from the mass balance. Biogas, fertiliser and hydrochar amount and composition depend on the raw material origin and quality. (As of June 2025)

|

| Funding Explanation |

On behalf of Federal Ministry of Transport (Reference number 3552.1)

|

| Technology Brief |

The pilot plant incorporates a combination of state-of-the-art and innovative processes, including methanation, anaerobic digestion (AD), hydrothermal processes (HTP), and several separation units. It is an integrated, intensely monitored, and highly automated plant that is operated in a 1000 m² experimental area at German Biomass Centre in Leipzig. The system’s modular design allows for flexible operation, enabling various processes to be combined seamlessly or operated individually.

Module overview regarding TRL: Anaerobic Fermentation (TRL: 9), Methanisation (TRL 8-9), Hydrothermal Processes (6-7), Separation Technologies (6-9); The pilot plant is not a comercially operation plant. It's a demonstration platform with different modules written above and different TRLs.

Additionally, the plant is designed to accommodate the integration of new technologies, which can be operated either continuously as part of the entire system or independently within individual modules. The robust design of the existing technology supports the use of a wide range of raw materials. Currently, the plant processes residual and waste materials such as wheat straw, cattle manure, green waste, and biowaste. The interconnected modules are configured to create a biorefinery concept aimed at producing renewable methane and value-adding by-products (fertilizer, hydrochar, etc.). With the addition of new technologies, the product range can be expanded accordingly. Potential target products could include methanol from biogas.

|

| Additional Information |

The pilot plant was planned, constructed, and commissioned at the DBFZ site as part of the Pilot-SBG research and demonstration project. The use of agricultural residues and municipal waste will be demonstrated in initial test campaigns. The integrated, automated, and digitalised plant concept combines both established and innovative technologies. It can process biogenic residues, by-products, and waste to produce renewable methane as the main product using green hydrogen. Thanks to its modular design, it can not only be flexibly combined and expanded, but also optimally integrated into the DBFZ’s research infrastructure and expertise. Process engineering research and development builds upon the scaling of the individual processes, which have already been established in multi-stage scaling at a smaller laboratory and pilot plant scale at the DBFZ. The process technology expertise at the DBFZ provides a solid foundation for potential expansion modules and the continued development of the research and development platform. Data acquisition and processing enable real-time measurement of parameters and process monitoring through extensive measuring points. This capability is supported by the DBFZ’s comprehensive analytics portfolio, which leverages its in-house laboratories. The robust data foundation facilitates iterative, real-time process optimisation and serves as the basis for modeling and simulating a digital twin. This digital twin enables the integration and advancement of AI-based process control. Additionally, the resulting mass and energy balances underpin the technical, economic, and ecological assessments. The multi-criteria assessment of supply chains includes not only an ecological evaluation focusing on greenhouse gas emissions but also an analysis of cost-revenue structures in the context of existing and foreseeable framework conditions. This approach identifies optimization potential not only for individual processes but also for interfaces and interactions within the process chain. Upstream and downstream steps, which are not directly demonstrated at the pilot plant, are also analysed with a view towards potential implementation on a commercial scale. The system integration of the concepts involves contextualising the results. The broad expertise of the DBFZ team allows for addressing questions related to mobilisation of the resource potential or integration of renewable hydrocarbons into existing infrastructure. The focus is on advancing and integrating the concept to contribute to a cross-sectoral sustainable bioeconomy and to provide high-quality co-products based on potential demand and market developments. The pilot plant is intended to evolve into a central component of an R&D technology platform for further research and development projects with industry and scientific partners. The high flexibility of the plant regarding the addition of new, innovative modules and the ability to detach individual plant components from the process chain and to operate them separately is an advantage. Furthermore, the integration within the DBFZ enables the comprehensive evaluation of promising technical innovations supporting market integration and making a meaningful contribution to the defossilisation of products.

|

|

More information: www.dbfz.de/pilot-sbg

|

Last Update: 2025-10-01 07:21:20