| Project Owner... |

Red Rock Biofuels

|

| Project name |

Commercial

|

| Status |

idle

|

| Startup |

2022

|

| Country |

United States

|

| City |

Lakeview

|

| State |

Oregon

|

| Type |

TRL 8 First-of-a-kind commercial

|

| Technology |

Fuel Synthesis

|

| Technology additional information |

FT-route

|

| Raw Material |

forest residues

|

| Input 1 |

dry wood (127,000 t/y

)

|

| Output 1 |

FT liquids (44,000 t/y

)

|

| Output 2 |

sustainable aviation fuels SAF

|

| Output additional information |

FT liquids include 40% diesel, 40% kerosene, 20% naphta

|

| Funding |

USD 70,000,000

|

| Technology Brief |

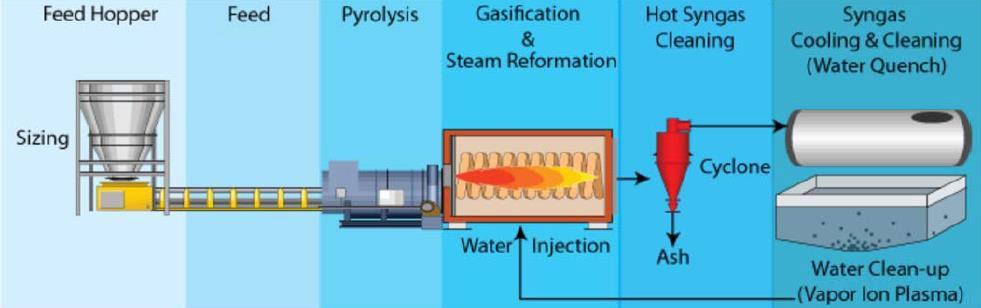

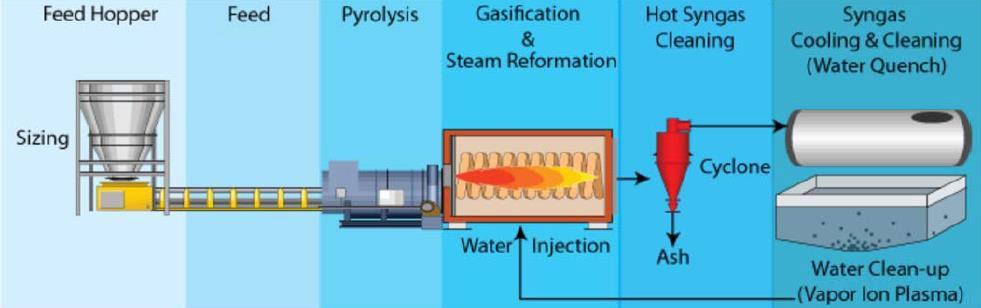

Red Rock has partnered with TCG Global on the gasification process. The FT technology selected comes from Velocys based on its Fischer Tropsch microchannel reactor technology for small-scale distributed production of biofuels, and this will be one of the first full-scale versions of this technology.

The TCG Global gasification technology has been tested by others in a plant that was constructed in Denver, Colorado for Red Lion Bio-Energy in 2004 at a scale of 9-25 dry tonnes/day. The gasification plant was in 2008 moved to Toledo, OH, USA, for the purpose of a DOE Integrated Biorefinery (IBR) project started in 2010 the primary objective was to upgrade the 23 tonnes/day Red Lion thermochemical conversion (TCC) system and build a new liquid fuel production (LFP) system supplied by Greyrock Energy that directly converts biomass into diesel fuel.

Construction of the plant in Toledo, started in April 2012. Plant performance and validation tests were initiated in Q2 2012 and seventeen test campaigns were carried out until Q3 2013. The integrated IBR plant was operated on wood, rice hull and other materials for a total of 992 hours and the gasifier for some 200 hours in addition, excluding start-up and shut-down periods.

|

| Additional Information |

Red Rock Biofuels have never been opened and was facing foreclosure.

|

|

Terry Kulesa

https://www.redrockbio.com

|

| Flowsheet |

|

Last Update: 2024-11-24 17:13:27