| Project Owner... |

TUBITAK

|

| Project name |

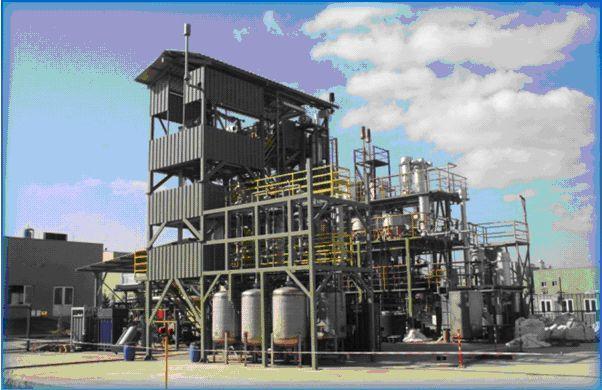

TRIJEN (Liquid Fuel Production From Biomass and Coal Blends)

|

| Status |

operational

|

| Startup |

2013

|

| Country |

Turkey

|

| City |

Gebze

|

| State |

Kocaeli

|

| Type |

TRL 4-5 Pilot

|

| Technology |

Fuel Synthesis

|

| Raw Material |

forest residues

|

| Input 1 |

combination of hazelnut shell, olive cake, wood chip and lignite blends (0.2 t/h)

|

| Output 1 |

FT liquids (250 t/y

)

|

| Funding |

EUR 8,500,000

|

| Partners |

As Project Executors: TUBITAK MAM, ITU, MU, HABAS,UMDE

As Customer Institutions: TKI, EIE

|

| Technology Brief |

The aim of the project is to develop and demonstrate the technologies for liquid fuel production from biomass and/or biomass-coal blends at the laboratory and pilot scale systems. The technological areas within the scope of the project are gasification, gas clean-up, gas conditioning, CO2 separation and liquid fuel production via Fischer-Tropsch (FT) synthesis. Activities related to the technological research areas consist of the pre-design of the units, laboratory tests, detailed design, engineering, manufacturing, commissioning and testing at pilot scale. In the gasification step, two types of gasifiers circulating fluidized bed gasifier and pressurised fluidized bed gasifier have been studied in laboratory scale (150 kWth). 1.1 MWth capacity pressurised fluidized bed gasifier have been designed for pilot scale. The aim of the gas cleaning step is to remove impurities from raw gas of gasifier. Both hot and cold gas clean-up technologies have been used in laboratory scale experiments. Hybride hot and cold gas clean-up pilot system has been designed. The third step of project is gas conditioning. The aim of this step is to adjust H2/CO ratio in syngas and capture CO2. H2/CO ratio in syngas will be adjusted in a water gas shift (WGS) reactor and CO2 will be captured by chemical absorption technique. One of the main work packages of the project is the production of liquid fuels via Fischer-Tropsch synthesis since the activities related to both FT catalyst development and fixed bed and slurry phase reactor applications have been performed in this work package. Low temperature FT process with multi tubular fixed bed reactor will be used to produce synthetic diesel in pilot plant. Iron based FT catalyst has been developed to convert syngas into hydrocarbon chains. All units of the pilot scale system are under construction currently.

|

| Additional Information |

currently lab scale experiments are being performed

|

|

Assoc.Prof.Dr. Fehmi AKGUN

fehmi.akgun@mam.gov.tr

Yeliz Durak CETIN,

yeliz.durak@mam.gov.tr

|

Last Update: 2024-08-07 08:20:50