| Project Owner... |

LTU Green Fuels

|

| Project name |

DP1+DME pilot

|

| Status |

idle

|

| Startup |

2011

|

| Country |

Sweden

|

| City |

Pitea

|

| Type |

TRL 6-7 Demonstration

|

| Technology |

|

| Raw Material |

other

|

| Input 1 |

Black liquor

|

| Input 2 |

Pyrolysis oil (co-gasif. with black liquor)

|

| Output 1 |

clean syngas (2 MW)

|

| Output 2 |

DME (4 t/d)

|

| Output 3 |

methanol (4 t/d)

|

| Partners |

For the Biosyngas program the partners are Chemrec AB, Haldor Topsöe, Volvo Truck, Preem, Smurfit Kappa, Sveaskog, Perstorp, Södra, Holmen, Flogas and ETC.

|

| Technology Brief |

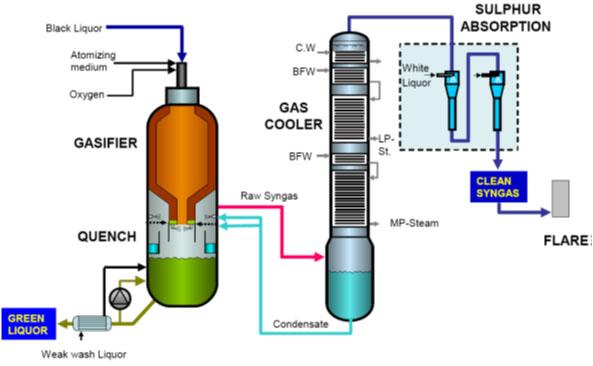

The Chemrec process uses a refractory-lined entrained bed reactor in which concentrated black liquor (or black liquor + pyrolysis oil) is gasified under reducing conditions at around 1000°C.

The liquor is decomposed in the reaction zone into melt droplets consisting of sodium compounds, and a combustible gas containing H2 and CO.

The smelt droplets and the combustible gas are separated in a quench dissolver where they are simultaneously brought into direct contact with a cooling liquid. The melt droplets dissolve in the liquid to form a green liquor solution. The gas leaving the quench dissolver is cooled producing steam. The cooling is done in counter current mode which means that the gas is efficiently washed of particulate matter. The gas is then free of melt droplets and can be scrubbed for H2S removal and then used as a clean fuel or syngas. The DME pilot was installed in 2011. Since the end of the Chemrec BLG program and the Bio-DME project in 2012, an industrially co-funded 160 MSEK R&D program was initiated in 2014 with the obejct ive of widening the fuel basis, develop new synthesis gas cleaning and synthesis reactror and catalyst technologies

|

| Additional Information |

Until May 2016 the plant has been operating as follows:

• Entrained flow gasifier: 27 000 hours, most of the time with pressure close to 30 bar and fuel flow rate corresponding to 3 MWth. The oxidant has after initial optimization been nearly 100% oxygen (and small amounts of nitrogen for safety and purging purposes). In the spring of 2016 we co-gasified pyrolysis oil with black liquor for over 1000 hours. The pyrolysis oil came from two commercial plants in Finland (Fortum) and Holland (Empyro) and was transported in trucks to Piteå, Sweden.

• Downstream syngas train: 12 000 hours, more than 1000 ton DME. In the last few months of operation we extracted slightly more than 50 ton raw methanol for testing purposes.

The DME and methanol has been used in field tests by partners Volvo Trucks, Flogas and Perstorp.

|

|

Rikard Gebart

ph: +46 920492196

email: rikard.gebart@ltu.se

|

Last Update: 2022-10-18 10:14:33